Company Profile

Jiangsu Feier Electromechanic Technology Co., Ltd. founded in 1988, is a high-tech enterprise focusing on research and development, production and sales of high-voltage coils, igniters and automatic winding machines.

Its headquarters is located in Rugao, Nantong of Jiangsu Province, which is reputed as"the hometown of longevity in the world"; it has excellent location and is endowed with the fine spirits of the universe. It only takes 37 minutes by high-speed rail train to Shanghai Hongqiao Transportation Hub through Shanghai-Nantong Yangtze River Bridge.

From"manufacturing" to "creation",from "following" to "running together" and "leading" in some fields, generations of simple, honest and progressive Feier people work hard with great concentration for more than 30 years, and write the responsibilities and roles of Chinese private enterprises with wisdom and sweat. At present, it owns solid technology, research and development strength, as well as 34 invention patents, and its product orders are increasing. It has become a bright new star at the converging point of coastal thoroughfare in the east of China and the golden waterway of Yangtze River.

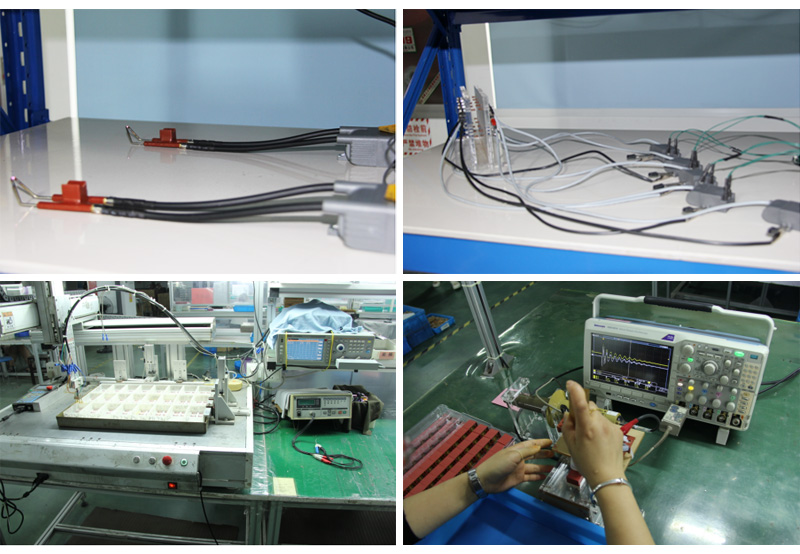

Laboratory

We have a professional laboratory with advanced testing instruments and equipment to carry out a number of tests for raw materials and products to ensure the stability and reliability of the products.

R&D Team

Our company has a strong development team. There are 10 design engineers,12 engineering departments and 8 afte-sales personnel. From new product development to production input to after-sales service, we will feedback customer demand within 24 hours.

Inspection of production

Strict inspection and testing are carried out for the production process and before shipment, and the dimensions, parameters and ignition performance of all products are tested. In addition, high and low temperature tests and durability tests are also carried out.

Independent parts processing

The company has 4 CNC deep processing equipments, 4 milling machines, 2 grinders, 2 spark machines and 8 wire cutting machines to meet customized needs and reduce development costs and shorten delivery cycle.

Location:

Location: